We’re often asked about refrigerated shipping containers, commonly known in the shipping industry as reefer containers. As we’ve already discussed, one of the primary issues encountered when building a container home is adding insulation. Without insulation, your container will be noisy and, more importantly, uncomfortably warm or cold depending on your climate.

Refrigerated shipping containers are a crucial part of the “cold chain”, a parallel supply chain that handles temperature-controlled goods. Products like meat, dairy, fruits, vegetables, and even flowers and pharmaceuticals often depend on the cold chain. If you’ve ever wondered how you’re able to buy fruits out of season, for instance, you can thank the invention of the refrigerated shipping container.

So, when looking at the various types of containers available, it’s natural to wonder if a refrigerated shipping container might be a better starting point than a traditional shipping container. A refrigerated shipping container is already insulated, saving you the time and expense of doing this step yourself, right? Well, the answer is a little more nuanced.

Let’s dive into a few aspects of refrigerated shipping containers, and see how they “stack up” to regular shipping containers (and yes, that was a container joke about stacking!)

Costs of Refrigerated Shipping Containers

The primary motivation people are interested in using refrigerated shipping containers for their container home is cost. The thinking is, if you can buy a refrigerated shipping container for just slightly more than a regular container, you wouldn’t need to pay to insulate it, and you’d come out saving money overall. Whether that’s true or not depends principally on how cheaply you can acquire a refrigerated container and how you would have otherwise insulated a regular container.

Broadly speaking, refrigerated containers cost around 50% more than the same size standard container. However, this figure depends greatly on where you are in the world and the prevalence of refrigerated shipping containers there.

Size of Refrigerated Shipping Containers

In order to talk about size, we first need to understand type. There are actually two types of refrigeration systems used in refrigerated containers:

- Integrated Refrigerated Containers (refrigeration equipment attached to and within the size footprint of the container)

- External or Clip-on Refrigerated Containers (refrigeration equipment that is temporarily attached to or otherwise placed near the end of a container, with ductwork feeding into and out of the container via portholes)

When most people think of refrigerated containers, they think of the integrated type, but it’s important to understand that it isn’t the only option. However, for the purposes of this article, assume that when we say refrigerated containers, we’re referring to the integrated type.

Refrigerated containers are available in most of the standard container sizes, including high cube (HC), so there is no issue with them interfacing with regular containers. However, what can be a problem is the internal floor area.

Given that the refrigeration equipment is integrated into the container, it has to fit somewhere. That somewhere, as shown in the picture above, is the end of the container.

Approximately the last two feet of the container is dedicated to refrigeration equipment, making your interior length two feet shorter. While two feet may not sound like much, it can be up to 5-10% of the length of your container, and correspondingly up to 5-10% of your floor area!

What might you have to sacrifice in your design to account for these two fewer feet of length? A closet? A couch? While this sacrifice can be worked around, it’s certainly something to consider.

Maybe you’re thinking to yourself, “What if I just remove the refrigeration equipment and reclaim the two feet of space that’s rightfully mine!?” This is an option, but not without its own issues. If you’re going to be reusing the refrigeration equipment (and we’ll address that below in the next section), you would need to fabricate a stand to hold the equipment, as the container would no longer be supporting it.

You would also have to extend ductwork from the refrigeration equipment to the container. However, probably the biggest issue of removing the refrigeration equipment and reclaiming the space is how to add the new open space to the existing closed space. To start with, you’d have to cut the end cap out of the container, push it out two feet and reattached it to the frame.

Then, you’d need to get two additional feet of exterior sheeting, insulation, and interior sheeting to cover the sides, roof, and floor. Clearly, it would be a major undertaking, and you may have trouble getting your two-foot addition to match the rest of the container.

Besides the two feet taken up by the refrigeration equipment, you also need to factor in the thickness of the insulation. A typical refrigerated container has 3-4 inches less interior width than a standard container. However, if you’re going insulate your container anyway (and you should!), this shouldn’t be a concern, as your self-installed insulation would likely take up about the same space.

Refrigeration Equipment

As previously mentioned, refrigeration equipment sits within the confines of the refrigerated container’s external envelope, but outside the enclosed space. The refrigeration equipment, much like your home refrigerator or air conditioner, is made up of mechanical equipment that requires electricity to operate.

When you buy a standard container, it has no moving parts other than the door hinges and locking mechanisms, so there isn’t too much that can break. However, a refrigerated container’s mechanical system has more ways to fail.

Assuming you don’t plan to use it, that’s not a concern. Many people go this direction and purchase NORs: Non-Operational Reefers. However, if you DO have aspirations of reusing the refrigeration equipment, it may need some repair work.

More important is how you would go about powering it. Most refrigeration containers are designed to receive electrical power from the ship during sea transit, and from the port while ashore. During land transit, they are typically powered by diesel generators called gen sets.

The electricity service needed is usually high voltage three-phase power. This is a more efficient method of power delivery for large industrial uses, as it allows the same amount of power to be transmitted across smaller diameter conductor wires.

However, most residential electrical service does NOT have this type of electrical power available. In order to use the refrigeration equipment, you need to modify or retrofit some of the subcomponents with alternatives that are compatible with the electrical service in your geographic area.

Refrigerant

Most refrigerators and air conditioners take advantage of a thermodynamic process known as the vapor-compression cycle. The cycle depends on specific components such as a compressor, evaporator, condenser, and expansion valve.

But the real magic of the cycle is the refrigerant, a special chemical that is the cycle’s working fluid. Unlike water that boils at 100⁰C (212⁰F) at sea level, refrigerants can boil at a much lower temperature, which is what enables them to absorb heat from a warm room.

Without getting too technical, just know that coupled with a refrigerant’s incredible utility for cooling is the fact that it can be poisonous and/or harmful to the atmosphere. If you choose to purchase a refrigerated container and don’t use the refrigeration equipment, it’s best to have a professional help you collect and dispose of the refrigerant, as these systems can and do leak over time.

Flooring inside Refrigerated Shipping Containers

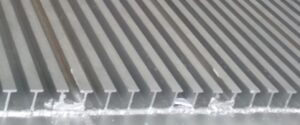

Unless you’ve seen a refrigerated container in person, you may not be aware of the design of their flooring systems. While traditional containers have smooth metal or plywood floors, refrigerated containers have special metal (usually aluminum) floors. This flooring system, called a T-floor, T-grating, T-style floor, or T-section floor, has a T-shaped profile that keeps the contents of the container elevated so that cold air can flow underneath.

The unmodified T-floor is not suitable for a container home, given the deep channels it contains that would hold dirt and catch the legs of your chairs and the toes of your shoes. Therefore, you would need to either put another floor on top of the T-floor, or tear the T-floor out and replace it.

Given that most people either replace the existing plywood floor or seal it in a typical container, modifying the floor in a refrigerated container isn’t necessarily more work, and you shouldn’t have to deal with any pesticides that manufacturers often use on the plywood floors of traditional containers.

Nevertheless, we recommend you think through this and have a plan in place that takes into account the time, expense, and interior ceiling height impacts of any modifications you are contemplating.

If you’re in a cold climate and have considered using radiant floor heating, the T-floor may be an advantage. With some modifications, you could use the channels to hold the water pipes for your radiant heat system, and then place plywood or other floor covering on top of the T-floor.

Walls of Refrigerated Shipping Containers

One final thing to keep in mind with refrigerated containers is the walls. Unlike traditional containers with corrugated steel walls, refrigerated containers have walls made of a sandwich of durable materials on both sides of the insulation.

This sandwich is typically made of stainless steel panels on both the interior and exterior with a thickness of 0.8 to 1.2mm. The exterior is often painted white, while the interior may be left uncoated. In some cases, you may find the interior made of a fiber-reinforced plastic instead that offers weight savings, chemical resistance, and simpler repair than stainless steel.

The wall sandwich is usually smooth on both the interior and exterior of refrigerated containers, which provides a different aesthetic than the corrugated steel of regular shipping containers. Depending on your design and appreciation for different visual styles, this may be a pro or con for you.

Cutting through that sandwich for doors, windows, and utility penetrations isn’t much more difficult than with other containers. However, you do need to make sure your interior and exterior holes match if you don’t have a cutting method that can cut through the thickness of the sandwich in a single pass. Given the presence of the foam, you need to be careful about fire and we recommend against using a torch for the cutting process.

Walls are also where most of your electrical outlets and plumbing fixtures are mounted. In standard container construction, you’d hide plumbing and electrical lines inside the interior walls where the insulation is placed.

Given that the walls of a refrigerated container are already built, you could cut through part of the wall sandwich (and remove the insulation) in order to place your lines, then cover over your cuts with new sheeting. Alternatively, you could just surface mount the lines on the interior of the wall sandwich. The first option is a lot of work, while the second will likely be unsightly.

Structure of Refrigerated Shipping Containers

We previously talked about the different materials used for the cladding on the walls, floors, and ceiling of a shipping container. However, the structural elements are pretty much the same as with regular shipping containers.

In most cases, the corners, top rails, bottom rails, and other main structural pieces are built from Corten steel as you would expect. This is what enables refrigerated containers to have a high level of strength, be stacked alongside regular containers, etc.

Summary

As you can see, the decision on whether to use refrigerated shipping containers for your container home is influenced by several factors that you may not have considered. Hopefully, this discussion will help you better understand the impact this decision will have on your build.

Unfortunately, with the great variability of prices and conditions of refrigerated containers, there is no universally correct answer on whether or not you should use a refrigerated container. Instead, weigh the various factors and make the best decision for you, your build, and your geographic area.

Additionally, one related item that we haven’t touched on in this post is insulated, unrefrigerated containers. These containers have no refrigeration equipment, and instead, rely on dry ice or other liquid vaporization processes that provide a finite amount of cooling over a few days or weeks. If you can find one of these containers, depending on other factors, it may make more sense for you than a refrigerated container.

29 Responses

Thinking of purchasing a reefer for a relocatable holiday/adventure cabin. This would involve removing refrigeration unit and installing fuel tank, generator, aircon, solar battery in the same space. Plausible or pipe dream? Also could solar panels be mounted in a recess on the roof so the container could still be stackable?

That sounds doable in theory, but you’d obviously have to measure everything to be sure. And it depends on the size of the generator (which in turn depends on what loads you anticipate having), how much fuel storage you want, etc.

There isn’t really an existing recess in the roof where you could mount solar panels. Creating a recess would mean removing some of the metal skin and insulation…not a good idea. One option would be storing the panels in the space vacated by the refrigeration unit, then folding them out on top of the container when needed. Another option would be using a regular height container but adding on an exoskeleton of sorts at the height of a high cube container. This would give you a ~1ft high clear space on top of the container roof where you could mount the panels. This would be tricky to build and difficult to certify if you were trying to ship internationally…but it could be done. Best of luck!

What an exciting read! I am tossing around the idea of putting a reefer container on 3 acres of remote land in Hillsborough Co Florida, all self contained and off grid. I’ve been terrified to reach out to the county to find out how many creative ways they will run my project through the ringer, but I am pretty set on doing this if I’m allowed. When I do call them, I’d like to be prepared.

I am currently an EE student and I have a pretty good grasp of structural and mechanical bits as well. What I cannot find is resources for information about the containers themselves. Can anyone link me to resources they know of about container building? Needing to know how thick the walls cavities are and the materials, the composition of the structural beams, the best methods to run electrical and plumbing on an elevated foundation, etc… All of this would be super-helpful in planning and dealing with the building department.

Thanks

Our website has the answers to most of your questions, so definitely keep browsing through the articles. Here’s two to get you started…

Interview with Shanti who build two container homes in Florida with reefer containers

Overview of Shipping Container Dimensions

Hi there !

I already built my house out of refrigerated containers and it went awesome (I tell this for those who are building and choose this way of doing it.. it’s very rewarding in the end), but nonetheless now I started to have a doubt due to a certain kind of possible loss of water through the ceiling and the loudness of the structure (they sound a lot when raining, for example..).

I want to know if as a solution could be if this ceiling can stand an ultra lightweight concrete base with a fall 5cm average, to avoid these two problems previously mentioned above, and at the same time that they can be tramped?

I anxiously wait for your recommendation if possible, here in Argentina where I’m from, almost anyone knows about containers.. it’s not so common around here..

Greetings from the south!

Fede

It’s hard to know for sure how it is made, as different manufacturers can sometimes take different approaches, and everything is hidden behind the walls now. Containers (including refrigerated containers) are made to support 300kg in a 300mm by 600mm rectangle in the weakest, middle part of the container. The container can definitely bend down with this weight on it, but to be certified it cannot have any permanent deformation. The question is if being ‘this’ strong equates to being strong enough to handle what you want to do.

If by tramped you mean that people will be regularly walking on top of the container as a type of patio, that’s definitely an added force that the container isn’t really designed for.

You should be able to find the density of the concrete you want to use, then calculate the weight by finding the volume of concrete you’ll place. Then you can decide if it’s a weight you’re comfortable with. If you place reinforcement with the concrete to give it more tensile strength, the concrete should be able to support itself and those walking on it and not really rely on the strength of the container’s skin underneath.

Fede

I would love to see some pictures of your container home. I have done several container mods ( doors and windows) I am unsure of how to weld my steel frames to the reefer container as it is aluminum and stainless steel. Just curious as you did that

thanks

john

Can one use a nibbler to cut openings into a Reefer?

That’s a bit hard to say. Normally it would work fine on the sheet metal covering, but the insulation behind it may get in the way of the lower nibbler jaw. You’ll also have ribs to deal with, especially on horizontal cuts. If you try it, report back and let us know!

Hi, There. Trying to get into a reefer building in Brazil and ur experience Will Helô a Lot! Hope tô achieve that!

Happy to help if we can. Email us via the “contact us” page and we can discuss your specific situation.

This is a question.

Would it be possible to revise the pipes within the refrigeration unit to make them function as a heat pump?

While technically possible, it’s not advisable. Every system is different, but in general, you’d need to redo some of the piping to add in a reversing valve that allows refrigerant to flow in both directions. A lot of the brains, wires, and sensors that control operations would also likely need to be changed.

I would like to know if anybody has used the internal pipes of the reefer to run water through it to be used like under floor heating?

Not sure what you mean by “internal pipes”. The reefer doesn’t have pipes running through it with fluid in them. All the cooling equipment is contained in the cooling unit on the end, and cool air blows through the container. The cooling unit itself would have some copper pipe in it that containers the refrigerant, but dismantling the unit, disposing of the refrigerant, and trying to use the pipe is a lot of work and mess for not very much benefit.

Anyone have on details on the structure for the reefers? Do they have a HSS tube frames with posts in the corners? Are there beams in the roof and floor?

While we haven’t seen one completely deconstructed and taken down to the frame, our understanding is that reefers are pretty similar structurally to other container types. Per ISO 1496, they are required to support the weight of eight loaded containers (among other static and dynamic loading tests).

Hi, do you know what the actual “R” value is of a Reefer? Cutting a hole in the wall for the windows, the supports in the walls, do you know how far apart they are, in a Reefer?

The answer to the R-value question is tricky. ISO 1496, which gives the specifications for insulated/refrigerated shipping containers, does not prescribe R-values, and instead gives a testing procedure for manufacturers to follow. We can infer the R-values by looking at the minimum allowable interior dimensions (which corresponded to maximum allowable wall thickness, as the exterior dimensions are fixed). There are two classes of insulated containers, with maximum allowable wall thicknesses of 9cm and 11cm. Different manufacturers may use different types of insulation in order to pass the test, but the highest performing insulations (like closed-cell spray foam) have an R-value around 3 per cm. So, that would imply that your wall would at most have an R-value of 27 to 33, depending on class of container. Note that this excludes the insulating performance of the interior and exterior metal surfaces. Also note that this is the maximum, but manufacturers may be able to pass the ISO 1496 test with less. Finally, note that the thickness is typically not consistent between sides, ends, floor and ceiling. We’re simply trying to give you some rough numbers here, but these can vary based on manufacturer.

As far as internal supports in the wall sandwich, this isn’t specified in the ISO 1496 standards, though in many cases there may not be any internal supports at all to minimize thermal bridging between the interior and exterior of the container.

Tom appreciate your site and checking out other people’s ideas.

REEFERS I already have two and have visions of using several more as the basis of a home.

There seems to me so many reasons why, I almost don’t understand how come more people haven’t discovered them

1. Apart from the obvious of insulation, to me they are ascetically better. a0 you could spray a concrete render on them and disguise the external appearance and they will not look like a container

2. The T channel in the floor seems a bonus and is almost designed for an underfloor heating system of pipework and then pour your slab over it polish it and, voila.

3. Reefers having carried foodstuffs are unlikely to have been fumigated by lord only know what poisons

4.the side walls are stainless steel and can be used as such, so a pretty chill interior at little cost

5. Hicubes, make sense, a sense of space and not pulling down the ceiling onto you. bit claustraphobic feeling is low ceilings

6. The structural aspedct of reefers, seems to me to be of a ribbed design with the insulation placed between these ‘metal joists’. So cutting in windows or doors is so much easier. Whereas the the strength of the standard container is in the wave of hgte material. Once you cut out door and window spaces you lose strength and start talking to expensive engineers.

7. At the moment I have 2 NOR Reefers, used as storage for cars and shed. NOR’s arte cheper, because they are Non Operational Reefers

8. Finally, I have made a bunch of scaled wooden blocks. Just leave then on the kitchen table, and it is interesting to see (in concret operational form) what shapes and external house designs look like. So easy to work as mock up models.

(I have considered with several NOR reefers I might be able to build a good working refrigeration system very economically)

For me, and the above reasons I think reefers are the cat’s whiskers

cheers Gary M

s

Gary,

Great to hear about your success with refrigerated containers. We’ll be making a few updates to the article in response to some of the points you and other readers have brought up. Thanks for helping out the container building community!

I’m building in a Hi Cube 12 metre (reefer).

Because its a Hi Cube, I have chosen to cut out some of the “T” floor beans so as I can form a channel which will house all plumbing, Heating radiator pipe work, and drainage which will still have sufficient fall to allow me to drain 2 hand basins, shower, bidet and kitchen sink through one outlet, through a hole in the LH door.

The Rayburn solid fuel cooker/range is the source of heating and cooking and the cast iron radiators have a return pipe for the heat spent waters. That return pipe along with the hot and cold water supplies to hand basins and shower will be in the 250mm (10 inch) wide channel which runs the length of the reefer.

There will also be 100 x 50mm (2″x4″) flooring joists supporting a plywood flooring. I amy be going over board” so to speak but all the timber will be treated timbers.

Actually, something that that others may be wise to know of, (and which I previously didn’t know of) is that the timber treatment of Pinus Radiata, (H3 & H4) which I understand is copper based, reacts negatively with steel and galv coated nails, so all fixings have to be made of stainless steel.

The ply flooring is glued and screwed with S.S. screws.

The strip where the plumbing is is all accessible by lifting out specifically cut ply strips which will be 310 wide and is the same width as a cork tile.

The flooring will be cork tiles for a number of reasons. Insulation qualities, quietness & comfortable underfoot and ease of cleaning to help keep the homes dust mites at bay.

Insulation ratings of the Insulated reefer is extremely good. The plane has always been to have a very warm home as well as having a highly economic & effective heating as well as excellent heat retention of our new home. After the time researching it, I decided that this Reefer was the way to go. Putting fluffy fiber-glass or even spraying foam about just wasn’t as good as with a system that the reefers come with. Urethane type insulation is ‘tops’ when it comes to R ratings & especially when its as thick as the reefer’s walls are!

I find it excellent for noise reduction as well.

I will be adding a solid native New Zealand timber to the walls of the rooms I construct. Its Rimu TG&V and then coating it all with oil based polyurethane.

The position of the final resting place is close to an electricity supply but we will be off grid totally but will have a 240 volt Genset plus solar panels for a 12 volt system.

The two sets of wiring systems wire will run in a suspended ceiling and in the ceiling cavity will be a sheet metal ducting system to extract dunny smells. shower steam and cooking fumes to an outside outlet.

In the same ceiling cavity will be the delivery plumbing for the heating radiators.

Anything that needs to be attached to the metal walls or ali ceiling, will be held in place with the use of threaded Rivnuts.

The original reefers refridgeration system will be removed to gain the extra space and to make access into another reefer which will be used for storage and possibly part of a workshop.

If you have any questions, feel free to ask.

Regards

Will

Will, sounds like a great project. Thanks for sharing some of your insight here. We’d love to hear (and see) more of the project when you get further along, so please do reach out via our contact page!

Jan 19m Haven’t been back here since the above was written.

Progress has slowed because of other unrelated tasks. I do have numerous JPEG images. How does one add them to the text?

Sorry but there is no way to directly embed pictures in the comments. You can link to an image hosting site though.

Hi Will

Thanks for sharing your experiences. We’ve just brought a 20ft reefer to convert to a tiny home in Southland. Would love the opportunity of talking with you. Are you happy to exchange contact details?

Hi Will

Would I love to learn more about what you are doing. We live in Rotorua and have plans to convert an old 12m Reefer as well. Where about’s in New Zealand are you?

Cheers

Simon

July ’18 Sorry Simon, I haven’t been back to this web site for some months hence no reponse to where I am.

I’m near Darfield, Canterbury

I have recently had more & more time to get back to the Reefers conversion and Im really happy with the progress.

A cobber is making a Youtube clip of the conversion but it might take a year to get it all sorted and posted.

I have re-read the description of Reefers by Tom and I’d recommend that he needs to work on one and understand they type of insulation they have in them, as well as the structural integrity & materials of a Reefer as well as measure up the space that the refrigeration unit is taking up, plus its removal.

I have 4 x 40ft Reefers and the refrigeration units of them on them take up about 350mm (14″ )

As well as that, they are all held in there, by a series of nuts which are able to be undone with either nut crackers (which splits the nuts) or with a half inch drive socket set with an extension, such as a bit of 3 or 4ft pipe to get greater leverage.

IF all of the nuts are removed, then ideally a tractor with a front end loader (with forks attached) or a fork lift would be most definitely helpful with its removal. Otherwise, a tug with a tow rope attached to a ute (small truck for them yanks) is highly likely to do the deed and then, just keep dragging it to a metal recyclers.

Then you have a hole to fill. The studs that were holding the refrigeration in place are able to be used to secure the End Blanking Cover’s material. Easy!

Then the inside is lined clean and more internal space available for cupboards or whatever. OR…. you could have another door or Bi-fold door or ranch-slider put in that end as well!

I am also about to cut into the side of the Reefer to put Bi-fold windows and a servery to a deck outside.

Also I’m working at cutting a hole in the side to install a couple of lead-light swing doors.

These doors will allow access (& heat from the Rayburn cooker) through into the living area which is part of the separate living and bedroom area. This is also a temporary moveable building which will be made of KINGSPAN panels)

I have considered using some of that Reefers waste material which came from where the the leadlight doors and Bi-fold windows are, to fill in the hole where the refrigeration set-up was but I want it to look tidy and also, its likely to take too much time sorting it. So…. so as to keep the Reefers same high R Rated insulation, I’ll look at attaching some Aussie made but European designed KINGSPAN (80mm thick) insulated panels in there.

I wouldn’t use closed foam or polystyrene. Ive waited to be able to afford better quality insulation with a much higher R rating.

Kingspan is pretty expensive but hey, I want this to last 30 to 50 years! (shhhhh, its temporary)

The Bi-fold window in the Reefers kitchen will have a thermal break built into the frame as well. (as do the other units french doors)

I really do hope folks wanting to build a home (or hut) in a shipping container, will seriously consider using a Reefer. The extra dollars invested when buying it, I feel SURE will be paid back with ease of setting it up and temperature COMFORT.

so sweet to hear. THANKS for the details.