Most people take the existence of shipping containers for granted. Yes, you occasionally see them stacked up at ports, but it’s easy to forget that almost every consumer product you use was probably moved via shipping containers.

You only need to go back a few decades to find a time when there were no shipping containers and no inter-modal transport systems. The more recent past offers us the example of innovators who realized the potential of building homes and other structures with shipping containers.

Even if you aren’t a history buff, there is useful information to uncover here about how economic needs drove the size, shape, and proliferation of containers that you’re able to make use of today.

Here we’ll explore how shipping was done before containers were invented, how and who invented shipping containers, the impact they have had on globalization, and how they’ve quickly grown in popularity as construction elements.

The World Before Shipping Containers

For centuries, mankind has voyaged across the seas, taking not only themselves but food, cotton, treasure, and goods, the likes of which their own country had never seen before. Just think of the Egyptians, Greeks, Romans, and more recently the British!

How did they transport their goods around the world? They clearly shipped to other countries, but without any standardization, it was a slow and difficult process.

Goods would be stored at a port warehouse until a boat was available. When an empty vessel arrived, these goods would be transported from the warehouse to the side of the docked ship. Goods would typically be loaded into sacks, bales, crates and barrels, and then they would be loaded by hand onto the ship.

As you can imagine this was a very labor-intensive process. This process was known as breakbulk cargo. A typical ship would have around 200,000 pieces of cargo onboard.

Towards the latter part of the second industrial revolution (early 1900s), this lack of standardization was becoming a real issue, especially considering how prevalent trains had now become. Transferring cargo from ships to trains was extremely slow and caused major delays and blockages within many ports. Larger ships would take around a week to unload and then reload (Levinson, 2006: The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger).

This was the only way to transport goods and for centuries this process remained unchanged.

The Incredible Vision of Malcolm McLean

There was a great need for a standardized method of transport, but for this to be realized, a whole host of industries needed aligning such as ships, trains, trucks, and port terminals. As you can imagine, it would require a lot of work and persuasion to make such a feat possible.

Many people around the world know the name Henry Ford yet Malcolm McLean is barely known at all. In just a few minutes, you’re going to understand why he was such an important contributor to the world.

Malcolm McLean was born in 1914 and grew up on a farm in North Carolina. After finishing school in 1931, he worked for several years to save up enough money to purchase a second-hand truck. In 1934, he launched his transport business. McLean soon scaled up his transport business and had five trucks running underneath him.

During a routine delivery of cotton bales in 1937, from North Carolina to New Jersey, McLean witnessed dockworkers loading and unloading cargo, which took hours upon hours. He contemplated what a waste of time and money this was.

From 1937 until the start of 1950, McLean focused on his transportation business, which had over 1,750 trucks and 37 transport terminals. In fact, it was the fifth-largest truck transportation business in the whole of America.

It was during this time period that several weight restrictions and levying fees were introduced to road transportation. It was not uncommon for McLean’s drivers to be fined for heavy loads of cargo.

McLean was now looking for a more efficient way to transport his clients’ cargo and was reminded of his experience in New Jersey back in 1937. This was when he had the idea of creating a standard-sized trailer that could be loaded onto boats in the volume of not one or two, like with his trucks, but in hundreds. He envisioned revolutionizing his transportation business by removing most of his trucks and using boats to transport the goods to strategically placed trucking hubs.

This would mean that trucks would only be used for short, intrastate deliveries, eliminating the weight restrictions and levying fees that had recently been introduced.

Intermodal Transport Shifts From Idea To Reality

McLean, convinced by his idea to create a standardized shipping trailer or container, sold his trucking business. In 1955, he took out a bank loan for $42 million. He used $7 million of this loan to purchase the established shipping company, Pan-Atlantic Steamship Company. Pan-Atlantic already had docking rights in many of the eastern port cities which McLean was targeting. Shortly after buying them, he renamed the company SeaLand Industries.

McLean worked with engineer Keith Tantlinger to design, refine, and test variations of the container and finally settled on a primitive form of what we know today as the shipping container. It was strong, standardized, stackable, easy to load and unload, and lockable, which made it theft-resistant.

If you’re curious, you can see some of McLean and Tantlinger’s original patents online (though they expired long ago): US3456967A, US3085707A, US2853968A.

So now McLean had his containers and the final piece of the jigsaw puzzle was designing ships that could hold the containers. He bought the oil tanker, Ideal X, and modified it to hold 58 of his newly designed containers, in addition to 15,000 tons of petroleum.

On April 26, 1956, Ideal X left New Jersey, heading for Houston. The success of his design was reinforced when the company was taking orders before the ship even docked in Houston to take goods back to New Jersey. This was mainly due to McLean being able to offer a 25% discount on the price of conventional cargo transportation at the time. Also, because the containers were lockable, it stopped goods from being stolen during transit.

Following the success of Ideal X’s maiden voyage, McLean ordered the first-ever ship specifically designed to carry containers: Gateway City.

Gateway City’s first voyage was in October 1957 and went from New Jersey to Miami. Incredibly, it only required two groups of dockworkers to unload and load the cargo. The cargo could be moved at a staggering 30 tons per hour, which was unheard of at the time.

Standardization of Containers

At this point, McLean was using 35-foot containers, different from the 20 and 40-foot containers which we see today.

However, there was still the issue of a lack of standardization with regard to the container’s size and corner fittings. This uniformity was needed so containers could be stacked efficiently. Additionally, trains, trucks, and other transport equipment required a standard-sized container so each method of transport could be built to a single size.

During the Vietnam War, the US government was looking for a way to ship goods more efficiently and was pushing for standardization. McLean’s SeaLand Industries was still using 35-foot containers, while industry rival Matson’s was using 24-foot containers. McLean agreed to release his patent of the revolutionary shipping container corner posts (vital to its strength and stacking) and several standards were agreed upon:

- January 1968: ISO 668 defined the terminology, dimensions, and ratings.

- July 1968: ISO 790 defined how containers should be identified (Replaced by ISO 6346).

As a result of these standards, we now have the 20-foot and 40-foot shipping containers, along with a few other less common sizes. In fact, 20-foot containers, called Twenty-foot Equivalent Units (TEUs), went on to become the industry standard for referencing cargo volume.

The Benefits Of Shipping Via Container

It took a mere ten years for the first international container ship voyage. In April 1966, SeaLand’s Fairland sailed from the US to the Netherlands with a whopping 236 containers on board.

From here, container ships saw a massive expansion, and in 1968, container ships had the capacity to carry around 1,000 TEUs, which was exceptionally large at the time. By 1970, SeaLand Industries had 36 container ships, twenty-seven thousand containers, and connections to more than 30 ports in America.

McLean eventually sold the company to R.J. Reynolds for $160 million. For more information on Malcolm McLean click here.

Many now claim that containers have been the single largest driver in globalization over the last sixty years.

- The cost to ship cargo has dropped more than 90%.

- In 1956, cargo cost $5.86 per ton to load, while now it only costs around $0.16 per ton.

- In 1966, around 1% of countries had container ports, but this rose to 90% by 1983.

- Malcolm McLean has been awarded “Man Of The Century” by the International Maritime Hall of Fame.

For more interesting data points about the adoption and popularity of cargo boxes, check out our Container Statistics article.

One interesting experiment into the spread of container shipping was the BBC Box. BBC, the British Broadcasting Company, used GPS technology to track a single container on its months-long voyage around the world in September of 2008. In total, it visited Europe, Asia, North and South America.

Pushback Against The Spread Of Container Shipping

Despite the incredible benefits offered by containerized shipment, not everyone was happy about it, and efforts were made to slow its spread around the world.

Traditionally, the process of loading cargo required lots of port workers to physically manhandle all of the goods into position. However, with containers, these workers were no longer required, which caused outrage with the dockside unions. During the early 1970s, many union workers went on strike, disrupting the shipping industry and shipping container’s rapid expansion.

However, due to the huge financial savings of containerized shipping, these union workers were paid severance agreements and shipping containers’ growth continued to skyrocket.

Why are there so many surplus containers?

We’ll cover some of the first people to come up with the idea of using containers for construction in a minute. First, we need to talk about why that was even an idea worth discussing.

In many western countries including the US, imports greatly exceed exports. These countries consume more than they produce, ignoring domestic shipments. And when this phenomenon occurs with regard to goods that are shipped via container, you often end up with a surplus of shipping containers in these countries. It’s sometimes cheaper to leave the container at its destination and buy a new one in Asia where most products are shipping from than it is to send an empty container back to Asia for reuse.

So, you might be wondering just how much of a shipping container surplus we’re talking about here. First, remember that container shipments in and out of ports are measured in TEUs (twenty-foot equivalent units). This unit of measurement is equivalent to one standard 20-foot shipping container.

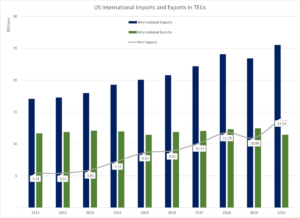

Let’s focus on just the United States for now, although similar statistics exist in many other western countries. The US Army Corps of Engineers Waterborne Commerce Statistics Center records container movements from US ports and is an excellent source of data. The below graph shows total US imports and exports via containers from 2011 to 2020. As you can see, the exports stay relatively flat over time while the imports continue to grow.

This graph shows that the trend is not new and is only getting more pronounced over time. And the difference between the exports and imports each year are containers that need to either be stacked and stored, introduced into the domestic shipping industry, shipped back overseas empty, or upcycled for some other use. So, while not all of these excess containers (around 14 million TEU’s in 2020, per the graph) are being stored at port facilities, the graph certainly indicates that there are an increasing number of empty containers that need to be transported somewhere else or reused in another way.

It’s also important to understand the subtleties of this data. It’s not measuring the value of what is being imported and exported, only the volume. In other words, this isn’t necessarily indicative of the health of a country’s economy or anything similar. After all, a country that imports pillows and exports diamonds would have a vastly different value (in dollars) versus volume (in TEUs) numbers.

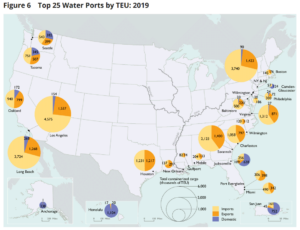

If you’re interested in more detailed data for the US in particular, we have you covered. The graph below shows how the import vs export numbers (along with domestic uses of containers between these ports or to the interior of the country) vary by port, as of 2019. Almost every port shows an imbalance, with more imports than exports, just as we’d expect based on the chart above. This graphic comes from the Port Performance Freight Statistics Annual Report to Congress in 2020, made by the US Department of Transportation’s Bureau of Transportation Statistics.

And if that’s not enough, check out the Bureau of Transportation Statistics Port Profile Dashboard Tool. This data dashboard lets you see tons of information, including TEU numbers, for dozens of US ports. There, you can probably see how the trade imbalance actually looks at the nearest port to where you live.

Now, some of you might be thinking, since we have such a big surplus of shipping containers in the US, could we not just recycle them into other steel products? The short answer is that it’s usually not very efficient to strip them of their non-metal materials then melt them down to steel. It’s equipment and labor-intensive just to get them cleaned up and cut into smaller pieces, then requires tons of energy to melt them down. For more information, read our in-depth article about the Sustainability of Containers.

Alternative Uses for Shipping Containers

If we look for the first official record of a shipping container home, we find a man named Phillip Clark. On Monday, November 23, 1987, Clark filed a patent called the “Method for converting one or more steel shipping containers into a habitable building”.

Within the patent, Clark outlines how shipping containers can be sited on a weight-bearing foundation to create a habitable building. He claimed that shipping containers make the perfect modular building material. He also commented that reused shipping containers can be used to make homes economically.

It took two years for the patent to be granted. On Tuesday, August 8, 1989, Clark was presented with his approved patent #US4854094A.

So where did Phillip Clark get his idea? Was he the first person ever to think that shipping containers could be used to build homes?

Far from it. Just two years before Clark’s patent was filed, shipping containers made their way onto the big screen. In 1985, in the film Space Rage, shipping containers were used to make numerous buildings on the production set.

We can go further back than that, to the 1970s, where UK architect Nicholas Lacey wrote his university thesis on the concept of reusing shipping containers and turning them into habitable dwellings.

He has since gone on to construct several of these shipping container buildings with Urban Space Management.

We can still find earlier examples of shipping containers being used as buildings, starting back in 1962.

On Friday, October 12, 1962, Insbrandtsen Company Inc. filed a patent titled “Combination shipping container and showcase”. Within this patent, Christopher Betjemann was listed as the inventor and it states that shipping containers can be used as an exhibition booth when companies are touring and showcasing their products.

Patent #US3182424A was granted on Tuesday, May 11, 1965. You can see the original patent here.

Going Mainstream

In 1994, Stewart Brand, an American writer, published a book titled “How Buildings Learn”. In it, Brand goes on to write ideas about how to convert shipping containers into office space. This was the first publication that mentions building with shipping containers.

From here, shipping container homes started to gain momentum and the first completed build we could find on record was the “The Simon’s Town High School Hostel”.

The project was conceived when Safmarine donated forty used shipping containers to Simon’s Town High School. The school wanted to use the containers to build a hostel that was capable of housing 120 people at any given time. The project cost a total of $227,000 and was ready for its first guests on November 30, 1998.

21st Century Shipping Container Homes

In 2006, Peter DeMaria, a Californian architect designed the first shipping container home in the US.

Known as the Redondo Beach House, the home was approved under the national Uniform Building Code (One of the predecessors of the IBC) and was completed in 2007. This was the first real shipping container home.

Since then we’ve seen shipping container homes popping up all over the world! Some of the more famous ones include:

Container Guest House (2010)

A single 40-foot container is used to build this container guest house. It has several unique features, but the most noticeable is the green roof!

View Details on the Container Guest House

Containers of Hope (2011)

Renowned for its incredible cost savings, Containers of Hope was built in Costa Rica for around $40,000. The home was built using parallel containers connected by a high-roofed space between, a building concept repeated

View Details on Containers of Hope

PV14 Container House (2014)

Proof that container homes don’t have to be small, the PV14 House used 14 shipping containers to create a sizable modern home in Dallas, Texas.

View Details on the PV14 Container House

The popularity of shipping container homes continues to rise and there appears to be no stopping these sustainable, affordable homes.

As shipping container home popularity continues to grow, we have seen many other amazing uses of shipping containers including restaurants, offices, and schools. Take a look at some of the other Shipping Container Case Studies for more cool examples.

Summary

It’s an interesting story that brought us these ubiquitous, nondescript boxes. Who knew that what we are now using to construct homes changed the world so much.

It’s unlikely that Malcolm McLean and his contemporaries could have foreseen the drastic changes they would cause in the world, nor the incredible examples of architecture that would result from their cargo-focused innovation.

Let us know which part of the history of containers most surprised you in the comments below!

12 Responses

Very well researched and covered all aspects.. including houses made of containers! Sharing it with my students for the extra edge. Thank you!

Glad you enjoyed it and thrilled to help inspire the next generation of shipping container enthusiasts!

This is so well researched and written. Thank you very much I just learned a lot and now more than ever wishing to pursue my dream of a container house here in Canada, Vancouver.

We have a street named ‘McLean Drive’: need to do some digging to see if it is after that same McLean as we have a pretty important container port here in Vancouver.

Thank you again and for all the references, I am going to check them all out!

Great to hear, glad you enjoyed it!

Wonderful and beautiful information

HAHAHA. An American, with a good Scottish name, came up with the idea of the container. Then along with the US Government standardized the containers in to 20ft & 40ft versions. Today ships are built to for those sizes, with 45ft versions sitting up top. HOWEVER the Americans, Canada included, use 53 foot or in a few case 60 foot versions that NOBODY ELSE CAN USE!

When did open top containers first get introduced?

Interesting question, and we unfortunately don’t know the answer. If you could find some historical copies of the ISO standards pertaining to containers, you might be able to see when they first started being referenced.

I believe it was actually Keith Tantlinger who invented the container concept we know today and Keith was hired by Malcolm MacLean. The containers which Sealand used commercially until the early 1980s were actually 35 footers.

There can be a grey area between who had the initial idea and who had the technical know-how to turn the idea into reality. Both McLean and Tantlinger certainly had a part in the creation of the containerized shipping industry we have today, so you’re right, we should include a mention of Tantlinger. And we should have said 35-foot not 33-foot, good catch!

Have purchased a container for my son. So hoping to transform into a batch for him.

Good luck Jacci!